Eurobike is in only 2 weeks now - and here are my predictions. Let me know if you want to meet us there and discuss how you can integrate our vastly superior torque/cadence sensing technology into your drive.

My Eurobike 2025 predictions - let us see if I am right:

The main complaint about the state of the business will be related to the orange guys’ silly market manipulation tariff on/off tricks (learn how you can also profit a bit from this with some TACO trading)

More micromobility vehicles. This started as a trade show that did not even allow e-bikes. This year, we will see even more micro-car-like EVs with less and less to do with bikes.

More of the usual “new products to drive sales” announcements, with at least one new “standard” the world does not really need. A dark horse prediction would be a total shift to a “right-to-repair” paradigm in e-bikes - not likely, but would be refreshing.

Less carbon and more metal frames, and more EU-manufactured bikes.

More “consumer electronics” companies launching innovative bike products and features. Continued slow (but steady) developments from the automotive-dabbling-in-bikes companies.

Don’t get me wrong. Eurobike is the best tradeshow I have ever attended, and I know the bike-energy is still strong. And we all love these “only in the bike business” crazy things that happen.

Bonus prediction 1: More increasingly overdone “cockpit” handlebars with integrated touchscreens and all kinds of silliness (with or without OnlyFans funding schemes).

Bonus prediction 2: Hall 10 is still an empty, unused hall in the middle; we all just have to walk around several times each day, wondering just why?

A FIRST - AGAIN

For Sensitivus - as a tiny company with a unique and next-level technology for lower cost and much better torque and angle/rpm sensing in e-bikes, Eurobike 2025 is going to be special.

For the second time you can try our torque/cadence sensing technology on bikes in the test area (not just prototype bikes in a “secret” corner). This time with a drive brand big enough to maybe actually matter.

I have had technology in products displayed by bike brands at all the shows for many years, but this time it feels special as it is only the second time our e-bike torque/cadence sensor technology is on show with a brand. This time, a brand that does have the muscle to actually get to some significant volume.

Does the final bike-feel really show off the big advantage of the strain gauge based sensor: zero-delay instant response? We don’t know yet. Last time we tried the prototype bike, it still had some of the delayed response feeling from the magnetostrictive sensor we replaced. It is a long time ago, so hopefully their room full of firmware engineers has been able to improve on it. We are quite excited to try it ourselves.

For some reason, our customers never really want to get the most out of us - which would be pretty easy by just making sure we have enough bikes to play with. Odd - but that is how business works sometimes.

BIZ STUFF

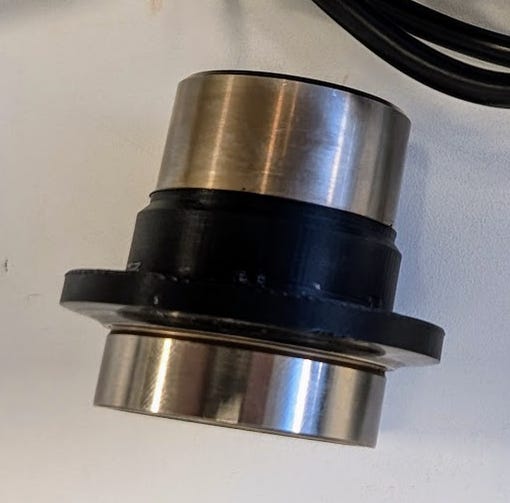

Some of the developments of the torque/cadence sensor technology we make are in the rotating element - we had a couple of projects where we were asked to replace a magnetostrictive sensor. So we got a few different designs done with this type of form factors:

This is the “torque tube” with the strain gauges and the electronics all sealed up. This communicates through a wireless link carrying both power, data, and angle to a stationary PCB sitting next to it. This PCB connects to the motor controller and provides 1ms torque, angle, and rpm data as input to the algorithm controlling how much motor-assist you get.

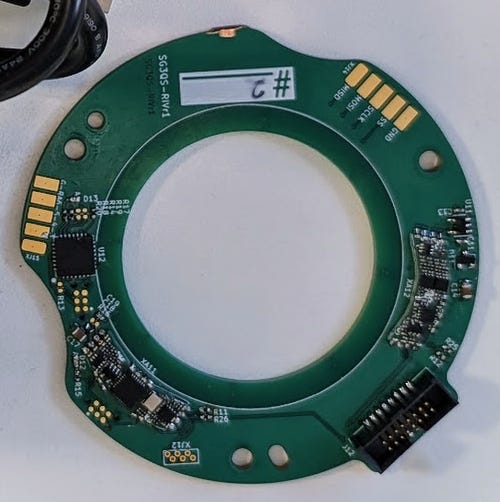

The stationary PCB could look like this in a prototype:

We also got into some more “flat” designs like this one, where the strain from the torque is measured on a disc-shaped metal part instead of a tube-shaped part.

We have gotten pretty good at making these prototypes quickly and in a form that is fairly close to the final performance, with everything nicely sealed in a good potting material to keep the performance over a very long time.

Design workshop

To make it easy to design a fully custom sensor without having to actually build anything physical, we developed a one-week online workshop to go through the needs of the application and design the crucial “torque sensing metal” together with the customer.

By performing the right types of 3D FEM simulations of this metal design, the performance of the final sensor is predicted so well that building a physical prototype is mostly for verification and other purposes.

With the degree of customization possible in this technology, we like to use this together with the designers of the drive unit to make the best possible solution. This is a high-volume game, so cost-sensitive. And 80% of the cost is driven by the initial design, so that is where we can help each other achieve the biggest and most meaningful cost savings.

FUN STUFF

I am on the fence with regards to Kickstarter. I know I ran a Kickstarter campaign way back (still top 1% of Kickstarter campaigns worldwide). Back then, it was clear and today even more so that KS is marketing more than it is innovation support for startups. Products are launched this way - not funded this way.

Lately, this campaign caught my attention. I like the idea. And I like the “open” model where someone is giving an open standard to the bike community to complement ANT+ and BLE. Only problem: It is NOT open in this case. It is just what I would call a false claim :-/

The idea is still good, and the bike industry still needs a good OPEN standard for connecting various devices like shifters, brake sensors, torque sensors, radars, lights, etc. - using both cables and wireless.

With this… enjoy your summer.

I will be back with more on the other side :)

Rolf V. Ostergaard

- Sensitivus

- EE-Training

- Linkedin

P.S.

If you found this interesting, there is more in the back issues. And if you found it boring, maybe the previous issues were more interesting for you.

P.S. #2

Why you should wait a bit before buying an ebike? Two good reasons:

The orange dude in the white house is reducing imports from China to the US for some odd reason (great idea to reduce consumerism and good for the climate, but clearly not his point).

That will likely mean you can soon get some really good deals on those same bikes, being dumped into Europe instead. If you are into that type of e-bikes :)If you are into the more sophisticated e-bikes with the ultimate ride feeling. You know, the type of e-bikes where you just smile because you don’t feel the motor at all. You just feel super strong (Yes, I know you have never tried one of those - but they are coming). You may soon be able to pick up one with our superior torque sensor technology inside, which can enable just that feeling.

P.S. #3

If you are looking for marketing help in the bike world for a consumer-facing *something* - check out our friends over at TwoTone. Cannot recommend these guys enough. Subscribe to the newsletter and look forward to their recap of EB25.

P.S. #4

If you are more of a robotics type, we could also meet at Automatica in Munich? I will be there looking to meet people with more industrial applications. A lot more boring, but equally well suited for good torque sensing technology.

Hope to see you out there somehow (please get in touch to set up a meeting time/place), and thanks for reading along :)

[[ … AND LET’S KEEP UNF*KING THE PLANET - ONE EBIKE AT A TIME ]]

Great issue! And thank you for the shout-out! : )