If there ever was a test of stamina and psyche. It is not Silk Road. It is running a Kickstarter. Bike stuff seems to be more over on Indiegogo - the little brother of Kickstarter. But beware. The creator requirements are stricter on Kickstarter, so that is where you want to be if you have a prototype of something you came up with and are trying to get pre-orders to get the first batch built.

Right now the active bike-related projects on Kickstarter are quite few - I found this one we can keep our eyes on. The bottlebag.

Launching soon :) I wish Anna Pfeifer from Konstanz the best of luck with it (the nice little town Konstanz where I used to stay back when Eurobike was still at Friedrichshafen).

Why do KS?

There are a few key things you need to understand about Kickstarter before you start one:

You bring 95% of the traffic, so build up that following way before, or be prepared to spend BIG on ads. If you want to succeed without ads, you pretty much need to get funded in the first day or two.

This is a marketing effort, not a funding effort. True, you can get some nice pre-orders, but the key thing you should expect to achieve is to get your name on the map in your category.

You should have much more than a prototype when you launch. The extra work handling all the backers will slow down your development, so be as ready and finished as possible. The average shipping delay on Kickstarter is still 9 months, and this may also happen to you. Even if you think you have everything under control.

Be prepared to spend a lot of time on backers. More than you think. Also, the toxic ones can really wear you down.

So if you are going to do this project anyway, a successful Kickstarter campaign is a great marketing vehicle. This proves you are legit and makes you a “known entity”. You will likely experience conversations that were difficult before, now go as if you are already shipping your product.

Why not?

See above. It is a lot of work. And if you are not prepared for it and the massive effort to deal with backers 24/7, you may simply burn out.

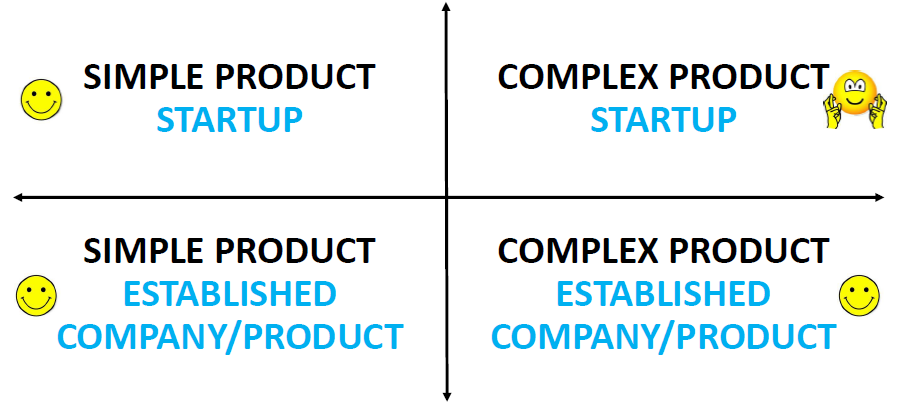

When I have given talks on doing Kickstarter, I have recommended you try to put your product in this matrix.

As you may have noticed, there are actually several established brands/companies that “fake” a Kickstarter in various ways as part of a creative marketing strategy. They are obviously in a different ball game. This is the lower two quadrants.

But if you are in the “intended” startup category (upper two quadrants), my best advice is to stick to a very simple product to improve your chances (top left). The stats are against you from the outset and putting a complex product with hardware, software, mechanical design, and more on Kickstarter is the most difficult you can do.

10% of all projects never receive a single pledge and 60.9% of all projects fail. There have been 361,513 projects in total that were unsuccessful.

Less than 5% of projects raise more than $100K, which may be the absolute minimum for most complex projects to break even.

Just do it

I don’t want to discourage you from doing it, but please go into it with the right expectations. And let me know when you launch - I may back you just to be nice (which is part of the reason KS is not really the market validation some see it as - KS backers are a funny bunch and not your average consumer).

Good luck :)

(my background for talking about this comes from running a successful Kickstarter and Indiegogo way back in 2016 - plus helping a few others with their campaigns.)

TECH STUFF

How about a(nother) standard sensor?

This is a torque/cadence sensor that is part of a super compact e-bike motor developed by some next-level guys in the US. Now we have packaged it up as a development kit - as one of the fastest ways to get started with the cool technology we have cooked up in Sensitivus. A sensor that beats everything out there for measuring torque and cadence on a bike (and a bunch of other places too).

We call it SG30 and it is a reference design for getting started with this technology. It is ready to use with the open-source Sensitivus SerialPlot software recently released. So really easy to get up and running on your desk - before jumping into integrating it into a motor/gear/prosthetic knee/cobot joint/whatever.

The trick to make this easy to play with is a genius 3D-printed plastic part that the two separate circuit boards snap onto. This sets a useful air gap between the two boards. And it centers the boards so the angle sensing works well. Angle is turned into cadence by the software in the sensor, but the fundamental measurement is the absolute angle.

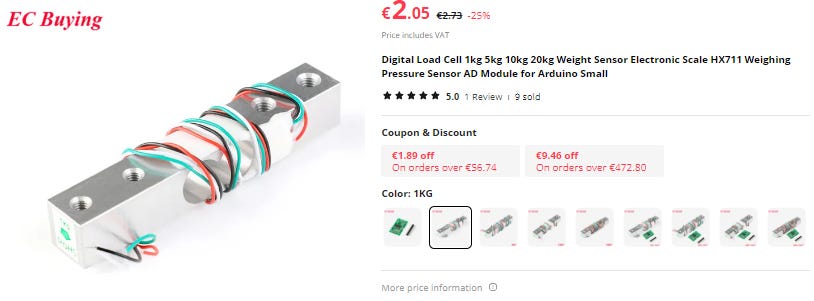

All you need to do is to solder it up to some strain gauges. If you don’t know how to do that - or don’t want to fiddle with that - there is always AliExpress :)

This will work and is maybe the easiest and cheapest possible way to get some strain gauges on a piece of metal. All sealed up and with easy-to-connect wires. This would be enough to play with both the angle sensing and the strain (aka torque) sensing on your desk.

Obviously, the idea is to put some strain gauges on a rotating shaft or other torque-sensing-metal and use the non-contact power & data link in the sensor to get that information out on the non-rotating part.

We have been struggling with how to make a “standard” sensor that is meaningful when *every* project we have seen so far ideally uses a custom sensor. This is another attempt at providing just that.

This type of sensor works well on a shaft. Bigger versions work well on a disc-shaped sensing metal (or spoked disc like a “spider” on a crank). This all depends on the application. Here is an example cross-section with the sensor on a torque-tube style metal shape.

Sensors are fun and we are starting to see more applications outside of bikes. Let us know if you have an application where a custom sensor could be useful.

FUN STUFF

Yet another example of silliness - taken to the power of at least two. But fun.

FRIENDS

CohAndCo

One of the more interesting bike frames - and with that series of bikes - is being created just across town from here in Copenhagen. These guys solved the problem of being able to replace belts in a really clever way, they created a modular dropout, and introduced a new type of frame molding technique.

The journal they keep online on their story and thoughts is well written and I enjoyed the latest take on why they choose the hub motor for their e-bikes. But don’t stop there. They have a lot of goodies in those articles. Great thoughts from great people.

ABOUT

I have been spending the last 10 years on sensors and technology for bikes. Both are things that I really enjoy. Technology for bikes can be many things - these are the types of products and technologies I can talk about from experience:

Power meters (to measure how hard you pedal for training purposes - but actually valuable for much more than just that). A product with a high retail price and a low BOM price. Mostly sold as after-market.

Case: Technology still on the market by THM - The Clavicula PM crankset.Brake sensors (for optimizing MTB downhill performance). Very niche product for elite riders, which may eventually slowly become more widely accepted. Pure after-market.

Case: Technology on the market from BrakeAce.

e-bike torque/cadence sensors (to make e-bikes feel more like “analog” bikes on a really “good leg day”). Super high volume product with a fairly low sales price - a pure B2B product for integration into a motor design or similar.

Case: Technology on the market from Sensitivus, but not quite out in stores yet.

Each of these examples has occupied a good chunk of my life over the last 10 years, but there is more. A lot more. This is a story for another day.

P.S.

If you found this interesting there is more in the back issues. And if you found it boring, maybe the previous issues were more interesting for you:

Why you need a power meter - open source or not

Why hub motors are better - and how Miri may be just the writer/photographer you are looking for

Why you should ride a bike to work - maybe even an electric unicycle

Why you should buy a new bike now - and why you should know TwoTone :)

Thanks for reading along :)

[[ … AND LET’S KEEP UNF*KING THE PLANET - ONE EBIKE AT A TIME ]]